– Equipments

Rinsing Screens

We offer wide range of washing & dryscreens.

Application: wash & dry screen. can be used in Gravel / RBM washing, Quarry dust/sand, Recycled material, Iron Ore and where the washing of material is required.

Features/Benefits

- Robust Designed

- Option of Rubber lined body available

- Fitted with special designed water jets ataccurate direction

- Option of PU mat and Wire mesh availablen: These wash screen can be used in Gravel/RBM washing, Quarry dust/sand, Recycled material, Iron Ore and where the washing of material is required.

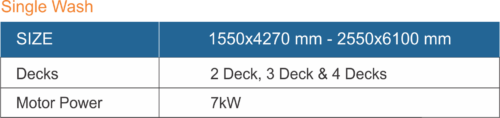

Vibrating Screens Wet & Dry

Our vibrating screens are designed for heavy-duty, long life, minimum

maintenance and low operating costs. We offer a full range of high efficiency inclined and horizontal screen swith circular and elliptical motion to suitall mineral and crushed stone sizing applications. special designed water jets at accurate direction Option of PU mat and Wire mesh available.

Models & Specifications

- 2, 3 & 4 deck configurations

- Huck-bolt construction for rigidity and long life

- Heavily built single shaft and double shaft vibrating mechanism with synchronized gears

- Circular & Elliptical screening motion

- Stroke amplitude and angle adjustment

- Double roll spherical roller self-aligning bearings

- Oil-bath lubrication for trouble free operation

- Adapttable for wire-mesh/rubber/polyurethane deck panels

- Low headroom for portable and stationary plants

Features/Benefits

- Simple and compact design

- Rugged construction

- Heavy duty application

- Durable and long life

- High quality and reliability

- Minimum maintenance

- Low operating cost

- Proven performance

Models

- SMVS4215-2D,3D&4D

- SMVS4818-2D,3D&4D

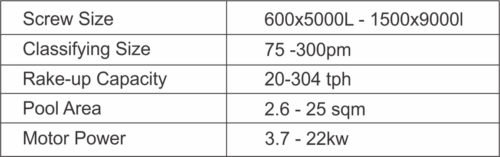

- These slow rotating screws are the ideal machines for fine material separation in mineral beneficiation plants.

- The washing, classification and dewatering operations are all combined in one machine for removal of

- unwanted fine sand recovery of useful mineral sandsands. We offer a wide range of sizes for varied classification requirements.

Twin Shaft Grizzly Feeders

Grizzly Feeders provide a continuous feed rate under a variety of loading and material conditions. Grizzly Feeders are designed to take heavy shock loads from trucks, shovels and loaders. This type of feeder can be used in quarries, recycling, industrial processing, mining, sand and gravel operations, and a wide range of mineral processing industries. Grizzly bars can be arranged as a single, double or even triple row dependent upon the amount of scalping required. Grizzly Feeders act as a coarse material separator while being designed to withstand the high impact forces found in aggregate primary dump loads.

Models & Specifications